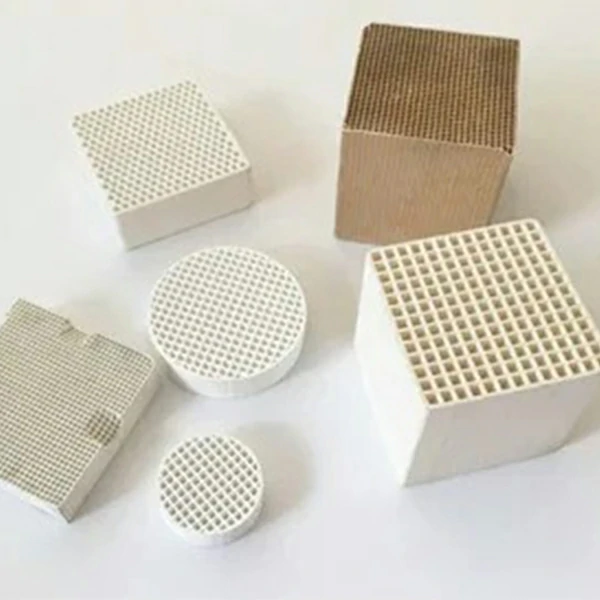

Honeycomb ceramics are advanced ceramic materials characterized by a unique cellular structure of hexagonal cells, resembling a natural honeycomb, which consists of numerous interconnected cells resembling a honeycomb. This design provides a combination of high surface area, lightness, structural strength, and durability, making them ideal for various industrial and technological applications. Below is a comprehensive guide to understanding honeycomb ceramics, their types, and applications.

What are Honeycomb Ceramics?

Honeycomb ceramics are made from materials like alumina, silicon carbide, or cordierite that are processed into a honeycomb shape. The structure features a network of small, parallel channels that allow for efficient air or fluid flow, which enhances their performance in heat resistance and filtration.

Types of Honeycomb Ceramic:

Alumina Honeycomb Ceramic:

Material: Made from alumina (Al₂O₃), a high-performance ceramic material known for its hardness and resistance to wear and corrosion.

Properties: High temperature stability, excellent electrical insulation, and chemical resistance.

Applications: Often used in high-temperature furnaces, catalytic converters, and insulation.

Cordierite Honeycomb Ceramic:

Material: Made from a mixture of magnesium, alumina, and silica.

Properties: Good thermal shock resistance, low thermal expansion, and high mechanical strength.

Applications: Commonly used in automotive catalytic converters, heat exchangers, and kiln furniture.

Silicon Carbide (SiC) Honeycomb Ceramic:

Material: Made from silicon carbide (SiC), a highly durable ceramic material.

Properties: Exceptional strength, high-temperature stability, and excellent thermal conductivity.

Applications: Often used in high-temperature gas filtration, kiln furniture, and aerospace applications.

Zirconia Honeycomb Ceramic:

Material: Made from zirconium oxide (ZrO₂), a ceramic with excellent resistance to high temperatures and thermal shock.

Properties: High fracture toughness, high temperature and chemical resistance.

Applications: Used in demanding environments like metal casting and welding, and high-performance insulation.

Key Benefits of Honeycomb Ceramics

Lightweight and Strong:

The honeycomb structure provides a high strength-to-weight ratio, making honeycomb ceramics ideal for applications requiring lightweight materials with significant strength.

Thermal and Chemical Resistance:

Honeycomb ceramics are resistant to degradation and retain their strength at very high temperatures. Depending on the material, honeycomb ceramics can withstand extremely high temperatures and are resistant to corrosion and chemical attack, making them suitable for harsh environments.

Thermal Shock Resistance:

Due to their low coefficient of thermal expansion, they can withstand rapid temperature changes without cracking., especially those made from cordierite or silicon carbide.

High Surface Area:

The intricate network of channels provides a large surface area for chemical reactions and gas-to-solid contact., making honeycomb ceramics ideal for use in heat exchangers, catalytic converters, and filtration systems.

Efficient Fluid Flow:

The open, parallel channels allow gases and liquids to flow through with minimal resistance. The open-cell design promotes excellent airflow or liquid flow, which is useful for applications such as gas filtration, combustion chambers, and reactors.

Applications of Honeycomb Ceramics:

The unique properties of honeycomb ceramics make them indispensable in several industries:

Automotive Industry:

Catalytic Converters: Honeycomb ceramics are used in catalytic converters due to their high surface area, which supports the reaction process for reducing harmful emissions.

Exhaust Systems: These ceramics help reduce harmful pollutants by filtering gases through the honeycomb structure. Used to trap and filter soot from diesel engine exhaust.

Aerospace Industry:

Heat Shields: Honeycomb ceramics are used as thermal protection in aerospace components, such as heat shields for rockets and aircraft.

Thermal Insulation: The lightweight and insulating properties make them ideal for heat barriers in space shuttles and other spacecraft.

Industrial and Power Generation:

Gas Filtration: In high-temperature environments, such as power plants and furnaces, honeycomb ceramics are used to filter gases, providing both structural support and filtration capacity.

Kiln Furniture: These ceramics are used in kilns to support products being fired in high temperatures without causing contamination.

Environmental and Energy Applications:

Environmental Catalysts: Honeycomb ceramics play a critical role in reducing environmental pollution by supporting catalytic reactions in exhaust gases. Used in various industrial processes for VOC (Volatile Organic Compounds) purification and other chemical reactions.

Heat Exchangers: Used in regenerative thermal oxidizers (RTOs) and regenerative burners to efficiently transfer and recover heat from exhaust streams.

Electronics and Electrical Insulation:

Insulators: Honeycomb ceramics made from materials like alumina and zirconia are used as electrical insulators in various electronic applications, from semiconductors to power transmission.

Filtration:

Air and Water Filtration: Honeycomb ceramics are used in various filtration systems due to their high surface area, which allows them to capture contaminants effectively.

Conclusion

Honeycomb ceramics are a versatile and high-performance material used across various industries, thanks to their lightweight, strength, and excellent thermal and chemical resistance properties. With applications ranging from automotive catalytic converters to aerospace heat shields, honeycomb ceramics are integral to improving performance and efficiency in many industrial processes.

Whether you’re looking for alumina, cordierite, or silicon carbide honeycomb ceramics, each material has its unique set of properties suited to different applications. Their growing use in industries like automotive, aerospace, and energy demonstrates their importance in developing efficient, sustainable, and high-performing systems.