The fire assay process is the industry-standard method for determining the concentration of precious metals like gold, silver, and platinum group elements (PGEs) in ores, concentrates, and other metallurgical samples. Known for its precision and reliability, this method has been used for centuries to provide accurate analysis, particularly in mining and metallurgical laboratories.

In this article, we’ll explore how the fire assay method for gold and other precious metals works, its key steps, and why it remains the most reliable assay technique in the industry.

What is the Fire Assay Process?

The fire assay process involves a series of precise steps to isolate and quantify precious metals in a sample. The method uses heat, fluxing agents, and a series of chemical reactions to separate valuable metals from waste materials.

1. Sample Preparation

The first step in the fire assay process is sample preparation. The ore or sample is crushed and ground to a fine powder to increase the surface area for better chemical reactions. Typically, a 30–50 gram portion of the sample is then weighed and set aside for analysis.

2. Mixing with Fire Assay Flux

Next, the ground sample is mixed with a fire assay flux. This flux typically includes a mixture of chemicals like lead oxide, soda ash, borax, and sometimes silica or flour. These agents help promote the separation of waste materials (gangue) and collect the precious metals into a molten phase.

3. Fusion (Heating in a Furnace)

The mixture is placed in a fire clay crucible and heated to high temperatures (around 1000°C) in a furnace. The flux assists in melting the sample and separates the gangue into a glassy slag, while lead or sometimes nickel is used to collect the precious metals.

4. Separation of Precious Metals

As the sample melts, the dense molten lead forms a “button” or “prill” that sinks to the bottom of the crucible, while the slag floats on top. The slag is discarded, leaving behind a lead button that contains the precious metals.

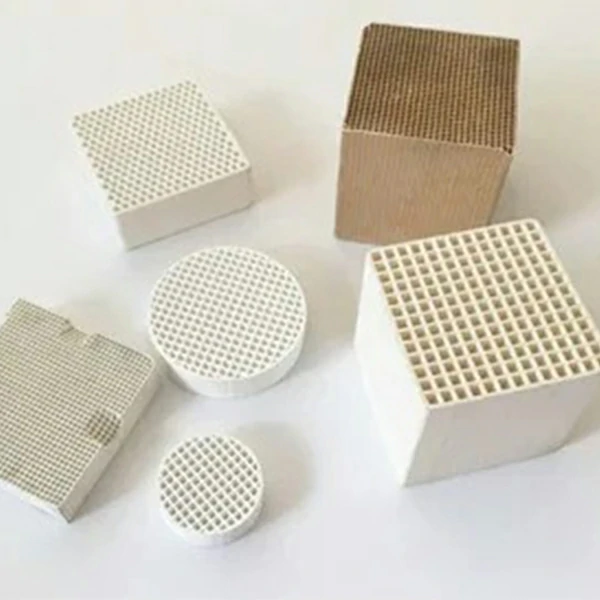

5. Cupellation Process

Once cooled, the lead button is transferred to a cupel, which is a porous, shallow vessel made from bone ash or magnesite. The cupellation process involves heating the lead button in a muffle furnace (around 900°C to 1,000°C). During this process, the lead oxidizes into lead oxide and is absorbed by the cupel or vaporizes, leaving behind a small bead (prill) of precious metals.

6. Parting for Gold and Silver

If both gold and silver are present in the prill, the next step is parting. This involves treating the prill with nitric acid, which dissolves the silver (and any other base metals) but leaves the gold behind. The remaining gold is washed, dried, and annealed to consolidate it into a pure form.

7. Weighing and Analysis

The final step in the fire assay method for gold involves weighing the precious metal bead (or just the gold bead, if parting was performed). This bead is then subjected to further instrumental analysis techniques like Atomic Absorption Spectroscopy (AAS), Inductively Coupled Plasma-Optical Emission Spectrometry (ICP-OES), or Inductively Coupled Plasma-Mass Spectrometry (ICP-MS) to determine the exact concentrations of precious metals.

8. Calculation of Results

The concentration of gold and silver in the original sample is calculated by comparing the weight of the prill to the weight of the sample. Results are often expressed in grams per tonne (g/t) or ounces per ton (oz/t).

Why Use Fire Assay?

The fire assay process is renowned for its unmatched accuracy and reliability in precious metal analysis. Here are a few reasons why it’s the go-to method for gold and silver assays:

High Accuracy: The fire assay method is considered the most accurate for determining gold and silver content in ores.

Established Technique: This assay method has been in use for centuries and is trusted across the mining and metallurgical industries.

Sensitivity: The fire assay method can detect even trace amounts of precious metals, making it highly reliable for low-grade ore samples.

Limitations of the Fire Assay Process

While the fire assay process is highly effective, it does come with certain limitations:

Time-Consuming: The entire process can take several hours, making it less ideal for quick analyses.

Destructive: The sample is consumed in the assay process, meaning it cannot be retained for other purposes after testing.

In Conclusion: The Importance of Fire Assay in Precious Metal Analysis

The fire assay process remains the gold standard for accurately determining the content of precious metals like gold and silver. Whether you’re a miner, metallurgist, or jeweler, understanding this process is essential for ensuring accurate and reliable results in precious metal testing.

By using the fire assay method for gold, fire assay flux, and advanced instrumental techniques, laboratories can deliver precise and and reproducible assay results that guide investment, extraction, and purityverification.

For industries dealing with precious metals, fire assays provide the confidence and accuracy required for effective decision-making.