In metallurgy and precious metal analysis, Fire Assay Cupels play a critical role. These small but powerful ceramic containers are used in the fire assay process, a centuries-old method still considered the most accurate way to determine the presence and purity of gold, silver, and platinum in ores, alloys, and recycled materials.

What Are Fire Assay Cupels?

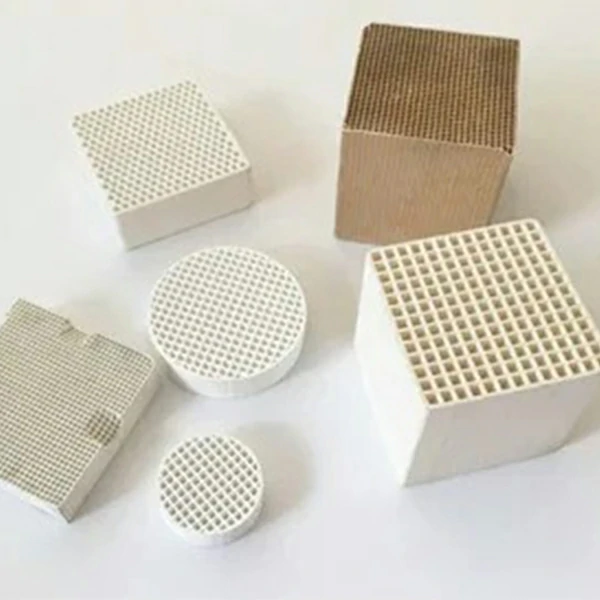

A cupel is a shallow, porous container typically made from magnesia, bone ash, or other refractory materials. Its unique absorbent properties allow it to soak up metal oxides like lead oxide during high-temperature assays while leaving behind beads of precious metals.

The defining characteristic of Fire Assay Cupels is their porosity, which enables absorption of impurities while maintaining structural strength at extreme temperatures above 1000°C.

Composition and Key Properties

Historically, cupels were crafted from bone ash, but modern production often relies on magnesia (MgO) for improved performance.

Superior Porosity: The highly porous nature of the cupels allows them to efficiently absorb molten lead oxide and other base metal impurities, ensuring that only the precious metals remain for a precise assay.

High Refractoriness: Engineered to withstand temperatures exceeding 1000°C, these durable fire assay cupels perform reliably under the intense heat of a furnace without any damage to their structure.

Minimal Absorption Loss: Modern magnesia cupels are specifically known for their very low absorption losses, which contributes to a more accurate and reliable final assay.

Essential for Accurate Analysis: The unique ability of these tools to isolate precious metals makes them the gold standard for testing and analyzing gold, silver, and platinum in a variety of applications.

How Fire Assay Cupels Work

The ore or sample is mixed with lead oxide and fluxes.

The mixture is melted in a furnace, oxidizing base metals.

The molten material is placed in the cupel, which absorbs lead oxide and impurities.

A bead of gold, silver, or platinum remains, ready for weighing and analysis.

This simple yet precise method has made Fire Assay Cupels indispensable in precious metal testing.

Applications of Fire Assay Cupels

Mining Industry: For exploration, ore grading, and precious metal recovery analysis.

Precious Metal Refineries: Used for quality control to determine the purity of bullion and other refined metals before they are released to the market.

Jewelry & Hallmarking: Authenticating the metal content of jewelry and crafted items.

Recycling & Salvage: To accurately assay the value of scrap materials and electronic waste that may contain precious metals.

Laboratories & Metallurgical Testing: Supporting R&D, refining, and quality control.

Conclusion

Fire Assay Cupels may appear simple, but they are fundamental tools in the accurate testing and refining of precious metals. By absorbing impurities while isolating valuable elements, cupels ensure precision in mining, refining, recycling, and laboratory applications.

Even in the age of advanced technology, Fire Assay Cupels remain the gold standard in precious metal analysis – trusted for their reliability, durability, and consistent performance.