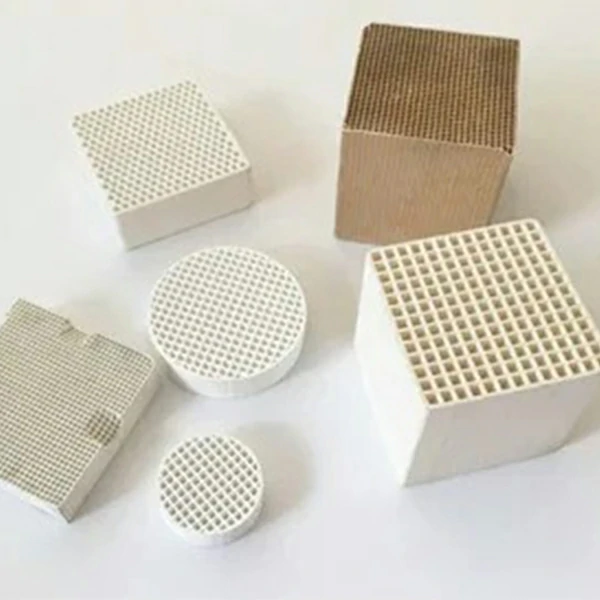

The Honeycomb Ceramic Catalyst Carrier is widely recognized for its efficiency, strength, and durability in various chemical and environmental applications. It serves as the foundation for holding active catalytic materials such as precious metals (Pt, Pd, Rh) and metal oxides (MnO₂, CuO, TiO₂). This unique honeycomb ceramic structure is essential in automotive catalytic converters, industrial gas purification systems, and chemical reactors, where high temperature, corrosion resistance, and reaction efficiency are critical.

Primary Reasons Why This Material is The Ideal Catalyst Carrier:

1. High Surface Area & Efficient Gas Flow

The honeycomb structure features hundreds of parallel channels per square inch, providing a large geometric surface area for catalytic coating.

- Maximizes the number of active sites for chemical reactions.

- Allows uniform gas flow with minimal pressure drop.

- Improves fuel economy and enhances catalytic efficiency in exhaust systems.

2. Excellent Thermal Shock Resistance

Honeycomb ceramics, especially those made from cordierite, mullite, or silicon carbide, have low thermal expansion coefficients, enabling them to withstand extreme temperature fluctuations.

- Prevents cracking or deformation during rapid heating and cooling cycles.

- Ensures durability under severe operating conditions in automotive and industrial applications.

3. Strong Mechanical Strength & Dimensional Stability

The rigid lattice design offers high compressive and flexural strength, maintaining structural integrity under vibration and gas pressure.

- Withstands temperatures exceeding 1000 °C without melting or warping.

- Ensures consistent gas flow and stable catalyst distribution during long-term operation.

4. Chemical Inertness & Corrosion Resistance

Materials such as cordierite, alumina, and silicon carbide are chemically stable and resist corrosion from acids, alkalis, and oxidizing gases.

- Prevents chemical degradation of the substrate.

- Extends catalyst lifespan and maintains high reaction activity.

5. Excellent Heat Transfer & Uniform Temperature Distribution

Thin honeycomb walls promote efficient heat transfer and temperature uniformity across the catalytic surface.

- Prevents localized overheating or hot spots.

- Ensures steady catalytic performance and energy efficiency.

6. Ease of Coating & Catalyst Deposition

The smooth yet porous surface of the honeycomb ceramic catalyst carrier allows strong adhesion of washcoat layers (e.g., γ-alumina) and uniform catalyst distribution.

- Enhances reaction efficiency and durability.

- Ensures even coating and consistent catalytic activity throughout operation.

Conclusion

With its combination of high surface area, superior heat resistance, mechanical strength, and chemical stability, the honeycomb ceramic catalyst carrier is indispensable in automotive, industrial, and environmental systems. It provides the perfect balance of performance, efficiency, and longevity—making it a core material in modern catalytic technologies.